What is a Warehouse Management System (WMS)?

A Warehouse Management System aka a WMS, is a software application that supports the management of warehouse operations, including controls and tracks the movement and storage of materials within a warehouse.

A Warehouse Management System WMS helps receive, store, and ship goods in and out of a warehouse. It manages the associated transactions, including receiving, putaway, picking, packing, and shipping.

A WMS typically includes:

1. Inventory Control: Maintains a record of all goods and materials in the warehouse. This includes tracking where items are located, how much quantity is available, and when they were received.

2. Order Fulfillment: Manages processes related to picking, packing, and shipping orders to customers. It ensures that the correct products are sent out in a timely manner.

3. Receiving and Putaway: Manages the process of receiving goods into the warehouse and putting them away in appropriate storage locations.

4. Warehouse Space Optimization: A WMS can help in layout planning to make the best use of space and ensure efficient picking and putaway paths.

5. Reporting and Analytics: Offers insights into warehouse operations, such as inventory turnover, order fulfillment rates, and warehouse capacity usage, which helps in making informed decisions.

A WMS can lead to increased accuracy, efficiency and speed in warehouse operations, and can greatly improve the overall supply chain management process.

One Network's Perspective on WMS

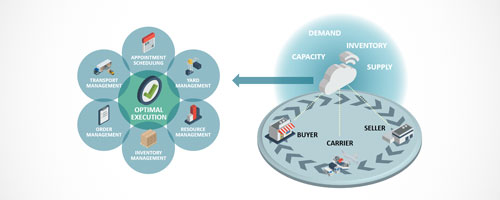

One Network’s NEO Platform is unique in that it offers a Warehouse Management System (WMS) that is natively integrated with other solutions, so that it can work intelligently to optimize transportation, orders, and service levels across the entire business network.

The WMS is a solution within One Network’s Intelligent Logistics solution. It is natively integrated with ONE's other solutions, including OMS, TMS, YMS. This enables it to leverage the multi-party nature of the platform to optimize warehouse operations while taking into consideration customer demand for orders, yard operations, dock schedules, and transportation operations.

One Network’s AI assistant, called NEO, constantly monitors the network and provides recommendations to help solve upstream and downstream issues that directly affect warehouse operations, thus helping streamline and prioritize the flow of goods into and out of the warehouse, to maximize customer service levels at that lowest cost.

Recommended Resources

One Network's Global Logistics Control Tower

Gain end-to-end visibility, insight and control over your transportation network. Learn how you can achieve 30-50% reduction in premium freight costs, 10-40% reduction in overall annual transportation costs, 2-10% increase in equipment utilization, and 12-50% reduction in manual planning.

One Network's Logistics Solution

Learn how ONE’s Transportation Management System (TMS) and Intelligent Logistics solution can lower your premium freight costs, increase asset utilization, reduce inventory, and optimize and automate your manual planning and execution processes.

Webinar: The Power of a Telematics-Enabled Control Tower

Telematics can provide real-time GPS tracking and sensor-based information for every shipment, and there is no doubt it’s a breakthrough technology. But for world-class supply chain execution, you need much more.