Production Planning & Scheduling

A Single, Accurate and Dynamic Order Forecast

The service can also account for all production constraints, including resource load-factor, production calendar, production batch size, manufacturing lead-times, and production frequency. With Production Planning and Scheduling, your scheduling staff can completely manage manufacturing schedules or production orders, from their initial creation to editing through an intuitive user interface.

The Real Time Value Network™ first generates a single order forecast that is continuously adjusted based on actual demand changes. The Real Time Value Network’s Production Planning and Scheduling service provides the ability to distribute a bill-of-material (BOM) based on actual demand to multiple partners to manage their part of the BOM, thereby keeping the BOM current and synchronized across all trading partner systems. The service can compute production plans based on the availability of materials and capacities to meet customer demand by balancing the load on the manufacturing resources after considering the high throughput capacity of the plant.

We knew we needed to find a way to deliver more value to our customers and trading partners while reducing inventory and operations costs. We’ve chosen One Network because of its unique and highly innovative technology.

- Global Director, Materials & Logistics, Dana

The solution provides your manufacturing scheduler with powerful visual tools that can be used to graphically optimize actual production orders across your manufacturing assets. These tools can be configured to meet the specific needs of your manufacturing operations. Finally, in conjunction with the Real Time Value Network’s Demand Translation tool, the Production Planning and Scheduling service can explode the Bill of Materials to source the netted raw material component forecast to the appropriate vendors based on open contracts and configurable sourcing policies.

Production Planning and Scheduling at a Glance:

- Distributes BOM to trading partners based on actual demand

- System computes production plans based on the availability of materials and capacities to meet customer demand

- Accounts for all production constraints (e.g. resource load-factor; production calendar; lead times; etc)

- Explode the BOM to source the netted raw material component forecast to the optimal vendor

Intelligent Supply Resources

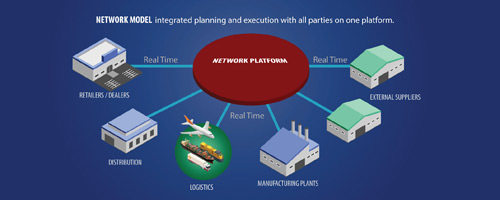

Supply Chain's New World Order

How companies can leverage the cloud for predictive and actionable supply network operations, integrated financial measurement, and integrated business planning.

Intelligent Supply

Plan, execute and collaborate across your entire multi-tier supply network, including your manufacturers, co-manufacturers, co-packers, component suppliers, raw material suppliers, MRO providers, and carriers. ONE Intelligent Supply improves your service levels while lowering inventory and operational costs.

Optimizing Direct Procurement

How business network platforms enable a new collaborative relationship between manufacturers, their suppliers, co-manufacturers, logistics providers and customers. Operate in real-time to optimize decision making, increase resilience, and unlock enormous business value for all parties.